Diagnostics & Prognostics

Automated equipment diagnostics and prognostics are becoming increasingly common. So-called prognostic and health management (PHM) technologies often provide equipment life cycle cost savings by enabling condition-based maintenance (CBM) programs as well as increasing system availability, reliability, and safety. The primary obstacle to developing and fielding PHM systems is the up-front cost of algorithm development and testing. Barron Associates’ main technical advantages over competing technologies are: (1) generic algorithms that can be ported to new platforms with relative ease, and (2) computational efficiency that will obviate the need for expensive custom hardware. Barron Associates has conducted diagnostics and prognostics research and development for NASA, ONR, NAVAIR, Army TARDEC, Lockheed Martin, Northrop Grumman, and many other entities.

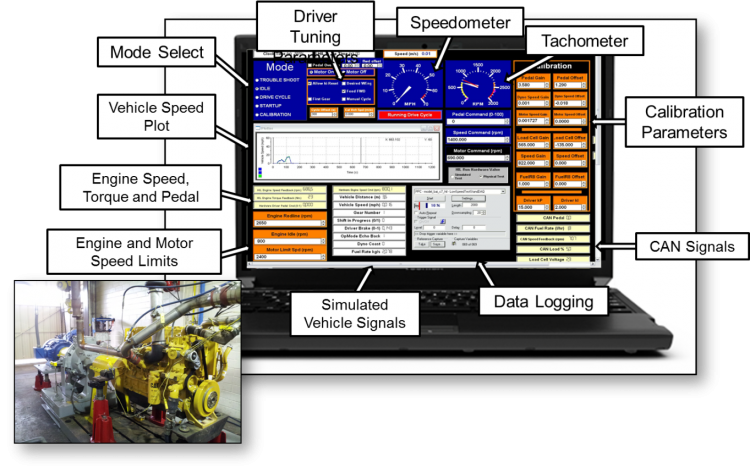

Barron Associates Diesel Engine Diagnostics Laboratory Setup

Barron Associates’ proven diagnostic and prognostic techniques provide:

- Adaptive model construction and parameter identification

- Analytic redundancy-based fault isolation

- Explicit sensor fault diagnosis and virtual sensor synthesis to replace a failed sensor

- Actuator fault diagnosis to enable fault-tolerant control

- Statistical change detection parametrizable to detect both slow-onset and abrupt failures

- Application to linear systems, nonlinear systems and systems with and without full state feedback

Target platforms have included

- Commercial transport aircraft

- Fighter aircraft

- Unmanned surface vehicles

- Unmanned air vehicles

- Diesel engines

- Military transport ground vehicles